A custom-made piece of furniture made by a master has several qualities that distinguish it from a mass-produced item.

How are custom cabinets made?

Some of the differences between store-bought and custom-made cabinets are obvious, while others may not be apparent to the casual shopper. The most notable distinguishing features of a furniture-grade cabinet are workmanship, materials and joinery. Let’s discuss those features in more detail.

Expect precision workmanship in custom cabinets

One thing factory-made furniture can’t give you is custom specifications tailored to your space and no other. A master craftsman can provide edge-to-edge design that uses 100 percent of your available space.

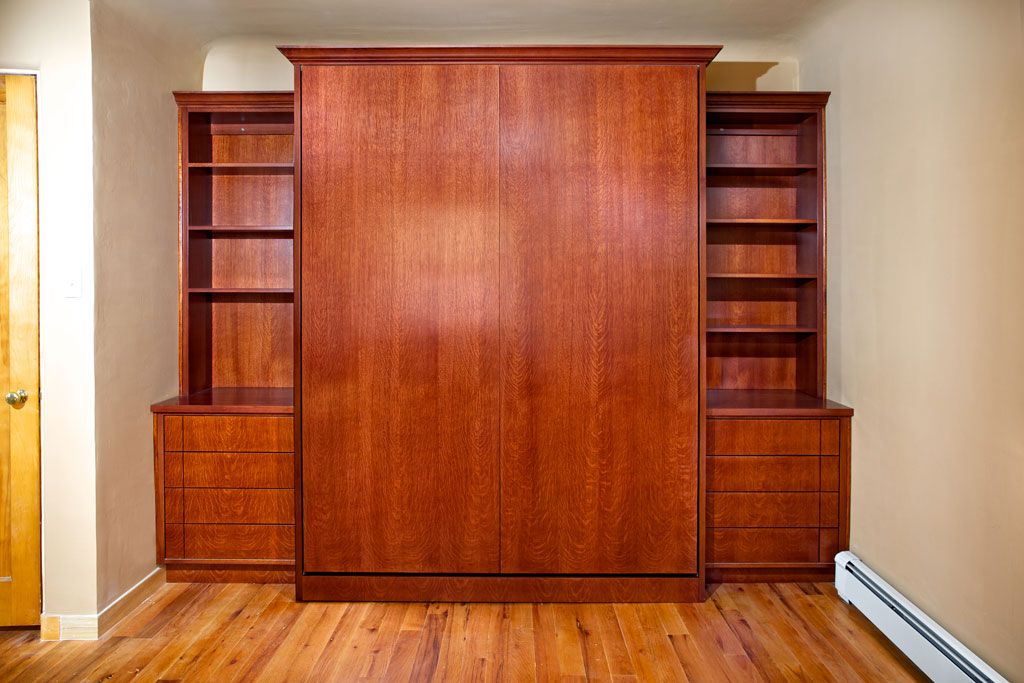

Here’s an example. This wall bed ensemble is striking for its continuous-grain detail. But it holds a design secret, too.

First, notice the wall-to-wall installation. This is only possible with truly custom measurements. Now take a look at the baseboard heater at the lower right.

Rather than eliminate the bottom drawer on that side of the room, we designed around it.

Only an expert who is willing to give your project the time and care it requires can help you create an heirloom piece that fits into your space so well, you’ll feel like it was always there.

Joinery is the cornerstone of high-quality custom wood furnishings

One of the most important differences between hand-built wood furnishings and mass-produced items is the quality of the joinery. Most furniture factories employ weaker joinery techniques like those shown below. Both the biscuit and the dowel methods will hold for a few years but with daily use will eventually fail.

Tony Rotter is committed to creating expertly built heirloom furniture and cabinetry, handcrafted with care to last a lifetime and beyond.

The way to make a joint more secure is to maximize the bonding surface area. To help our furniture and furniture-grade cabinetry stand the test of time we use a hybrid type of joinery that starts with a traditional mortise and tenon in combination with a custom milled tongue for increased structural integrity. This process allows us to roughly double the bonding surface in the joint. The additional surface area, combined with today’s strong bonding agents, creates a joint that is incredibly strong and beautiful.

High-density core plywood – what you can’t see matters

Even if you shop for hardwood products, you may be offered pieces built with particle board in the interior. Due to rising costs and other factors, many builders use particle board or MDF for cabinet carcasses, shelves and drawer sides. Particleboard lacks strength and can perform poorly when exposed to moisture (such as in kitchens and bathrooms).

Tony Rotter uses high density engineered wood for cabinet and drawer interiors. This product has a high-density core that is stronger than natural wood or particleboard. Alternating grain construction gives it great strength and stability. High density engineered wood comes with either a plywood or a fiberboard core, and both options make for an excellent finished product.

Tony takes another extra step to create durable, long-lasting furniture bones. To finish the cut edges of high-density material, Tony mills out a channel and permanently bonds in a hardwood insert. Mass producers of cabinets, on the other hand, use an iron-on thin veneer to hide the end grain.

Although edge banding takes more time, it gives the owner the option to refinish or repair the piece in the future, should it ever suffer from the wear, dents or dings that everyday use can cause. Planning for your cabinets’ second finish is one more way we ensure that our product will serve you for many years and is far superior to mass-produced options.

How much do custom cabinets cost?

With all the advantages of custom cabinets – higher quality materials, expert workmanship, the ability to use every inch of available square footage – many people assume the price is significantly higher than the price of store-bought cabinets. You might be surprised to learn that the difference in total cost can be insignificant.

Mass-producers typically price the most basic configuration first, knowing you’re likely to request add-ons as you learn more. For example, customers typically want upgraded hardware on the full-extension drawers to hold heavy cookware or canned food, and soft-close hinges on cabinet doors. We know that these are standard features customers expect, and we include them. Factory-made cabinet sellers charge extra. Once you start comparing apples to apples, big-box store cabinets aren’t much of a deal after all.

Even within the constraints of the extremely high-quality standards to which we hold all of the furniture made by Tony Rotter Woodwork, we can offer both premium and money-saver options.

The best way to find out the true, actual cost each competitor will charge for your cabinets is to provide them with a full set of architectural drawings to bid, and ask each one to detail what’s included in the bid. Compare the plywood, the joinery, the hardware, the door style, the drawer style, and the finish. Invariably, lower pricing comes from lower quality.

Contact us today to get more information about how we can build heirloom wood furnishings and cabinets for your space.